Description

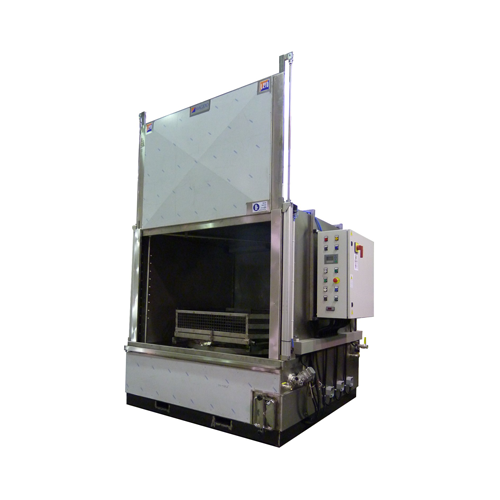

Magido L-210 Parts Washer: Efficient Cleaning for Heavy-Duty Operations

The Magido L-210 Parts Washer is your go-to solution for heavy-duty production and maintenance parts washing. Designed with space-saving efficiency in mind, this front-load washer combines power, durability, and ease of use.

Magido L-210 Front Load Spray Wash Cabinet Key Features:

- Space-Saving Design:

- The front-load space-saving design makes the L-210 aqueous parts cleaner ideal for heavy-duty parts cleaning.

-

- Simply load your parts, close the door, and let the automatic wash process take care of the rest.

- Durable Construction:

- Crafted from 304 stainless steel, the L-210 front load spray wash cabinet ensures longevity and resistance to corrosion.

- The 304 stainless steel pump and Incoloy heating elements guarantee reliable performance.

- Efficient Cleaning Process:

- The Magido Front Load L-210 top-load parts washer utilizes the power of angled spray nozzles and a rotating turntable.

- These features ensure thorough cleaning of your parts, leaving them spotless and ready for use.

- Additional Features:

- Fluid Level Sensor: Auto-fill capability for hassle-free operation.

- Removable Isolation Floor & Chip Basket: Easy maintenance and debris removal.

- Steam Exhaust Fan: Efficient ventilation during operation.

- PLC With HMI Touch Screen: User-friendly controls for precise settings.

Top-Load Parts Washer Applications:

- Automotive Shops: Keep your nuts, bolts, and engine components clean and well-maintained.

- Manufacturing Facilities: Optimize machinery performance by ensuring clean parts.

- Transmission Remanufacturing: Maintain precision and reliability in transmission components.

|

Features:

- Durable 304 Stainless Steel Construction

- 304 Stainless Steel Pump

- Incoloy Heating Elements

- Fluid Level Sensor Auto Fill Combination

- 304 Stainless Steel Turntable

- 304 Stainless Steel Spray Bars With Optimized (V-Jet) Wash Nozzles

- Attached Load Table or Roll Away Turntable Cart

- Removable Isolation Floor & Chip Basket

- Removable Tank Access Panels

- Steam Exhaust Fan

- Drain Pump

- Removable Tank Access Panels

- Automatic Door Closure With Safety Controls

- PLC With HMI Touch Screen

- Tank & Cabinet Insulation

Options

- Additional Cleaning Stage (Heated Wash/Rinse)

- Continuous Rinse To Drain

- Heated Dryer

- Air Blow-Off

- Filtration

- Oil Water Separator

- Oil Skimmer

- Steam/Mist Collector

- Chemical Proportioning System

- Expanded Load Weight Up To 5,000 lbs.

- Automatic Load/Unload

- T-Shaped Load Table

- Stack Light Tower

- Dual Load Doors For Continuous Wash Operations

- Expanded Load Height

- Expanded Fluid Capacity

- Pump Upgrade 15/20+ HP