Description

How it Works

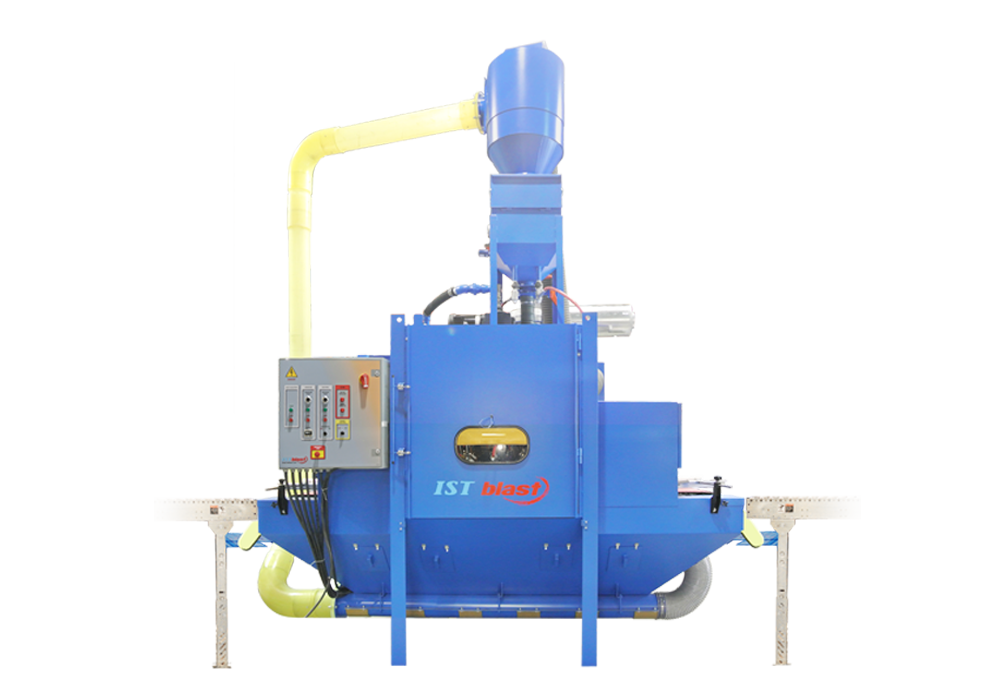

All the pass-through blasters are designed to achieve the best performance and output for a given application. The shape/size/weight of the parts, process requirements, production rate target, and feeding method will influence the machine’s final design. Generally speaking, parts are loaded on a conveyor either manually by an operator, or automatically with the use of a robotic arm, pneumatic/mechanical loader, or in full integration with the production line. Parts are conveyed to the blasting zone where they are blasted by fixed nozzles, moving nozzles, or nozzles mounted on a rotary head. As they exit the blasting area, parts are cleaned by blow-off nozzles. In some cases, parts must be flipped and returned to the blasting area, or are kept in constant rotation as they travel on the conveyor to ensure a complete coverage of the surface. Dust and airborne particles are contained within the blasting area and exhausted to the dust collector while blast media is collected at the bottom of the cabinet, cleaned by a cyclonic separator, and returned to the storage hopper for further use.