Solvent Recycling Systems

Solvent Recycler Advantages

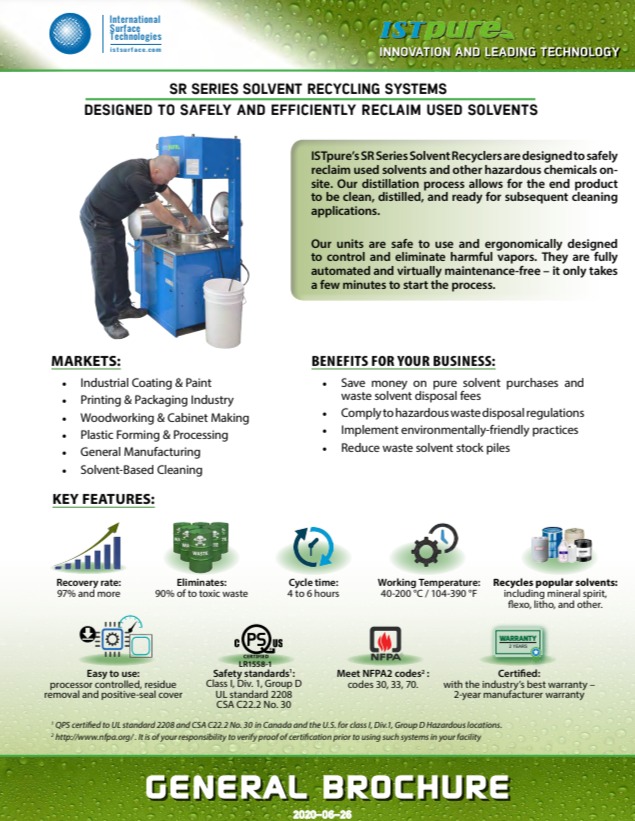

- Durable: Built with robust, corrosion-free stainless-steel tanks.

- Cost-effective: Most of our clients have achieved a return on investment (ROI) in as little as 4 to 12 months

- Virtually Maintenance-Free: Require low maintenance and supervision, a simple 4-hour maintenance routine every 2,000 hours of operation.

- Fully Automated Process: Operate on a fully automated process assisted by a PLC with predetermined parameter settings and built-in alarm signals.

- Certified in North America: Certified to UL standard 2208 and CSA C22.2 No. 30 in Canada and the U.S. for class I, Div.1, Group D hazardous locations, and meets NFPA codes 30, 33, 70.

- Guaranteed: Backed up by industry’s leading 2-year manufacturer warranty.

Solvent Recycling Systems FAQS

How can a solvent recycler help optimize manufacturing processes?

Solvent recycling can help optimize manufacturing processes by providing a number of benefits, including:

- Cost savings: Solvent recycling can significantly reduce the cost of purchasing new solvents. By recycling solvents, manufacturers can reduce their overall solvent usage, which can lead to significant cost savings over time.

- Improved efficiency: Using a solvent recycler can help improve the efficiency of manufacturing processes by reducing the amount of time and resources needed to manage and dispose of used solvents. This can help to streamline processes and reduce overall production time. Additionally, clean solvent cleans faster. As solvent becomes saturated with oil and other contaminants, it takes longer to clean and more labor costs.

- Environmental benefits: Solvent recycling can help reduce the environmental impact of manufacturing processes by reducing the amount of waste generated and reducing the need for new solvent production. This can help to improve sustainability and reduce carbon footprint.

- Reduce “Cradle to Grave” Liability: Hazardous waste leaving your facility is your responsibility even after leaving your site. Reduce this liability by keeping your hazardous waste stream onsite and recycling.

- Improved quality: Recycled solvents can be of equal or higher quality than virgin solvents, depending on the quality of the recycling process. This can help to improve the quality and consistency of manufactured products.

Overall, a solvent recycler can help manufacturers to optimize their processes by reducing costs, improving efficiency, reducing environmental impact, and improving the quality of their products.

What are the environmental benefits of solvent recycling?

A solvent recycler can provide several environmental benefits, including:

Reduced waste: Solvent recycling reduces the amount of waste generated in manufacturing processes. Recycling solvents instead of disposing of them reduces the need for landfill space and decreases the amount of hazardous waste that needs to be treated and disposed of.

Reduced emissions: Solvent recycling can reduce emissions of volatile organic compounds (VOCs) and other air pollutants. VOCs are a major contributor to air pollution and can have negative impacts on human health and the environment. Recycling solvents reduces the need for new solvent production, which can decrease the amount of VOCs emitted during manufacturing.

Reduced energy consumption: Solvent recycling can reduce the energy needed to produce new solvents. The production of solvents is energy-intensive and can contribute to greenhouse gas emissions. By recycling solvents, manufacturers can reduce their energy consumption and decrease their carbon footprint.

Improved sustainability: Solvent recycling promotes sustainability by reducing the amount of virgin resources needed to produce new solvents. By conserving resources, manufacturers can reduce their environmental impact and promote more sustainable manufacturing practices.

Overall, a solvent recycler can provide significant environmental benefits by reducing waste, emissions, energy consumption, and promoting sustainable manufacturing practices.

What are the benefits of a solvent recycler?

A solvent recycler is a machine that recycles used solvents by distilling them, separating the solvent from contaminants, and producing a clean solvent that can be reused. There are several benefits to using a solvent recycler, including:

Cost savings: Solvent recyclers can significantly reduce solvent costs by allowing businesses to reuse their solvents instead of disposing of them and purchasing new ones.

Environmental benefits: Solvent recyclers help to reduce the amount of waste generated by businesses, as they allow used solvents to be recycled instead of being disposed of. This helps to reduce the environmental impact of solvent waste.

Improved efficiency: Solvent recyclers can improve the efficiency of cleaning processes by ensuring that clean solvents are always available. This can help to reduce downtime and improve productivity.

Reduced hazardous waste: By recycling solvents, businesses can reduce the amount of hazardous waste they generate. This can help to reduce the regulatory burden associated with hazardous waste disposal.

Improved quality control: Solvent recyclers produce clean, high-quality solvents that are free from contaminants. This can help to improve the quality of products produced by businesses that rely on solvents for their manufacturing processes.

Overall, solvent recyclers offer several benefits to businesses that use solvents in their operations. They can help to reduce costs, improve efficiency, reduce waste, and improve the quality of products produced.