Description

How It Works

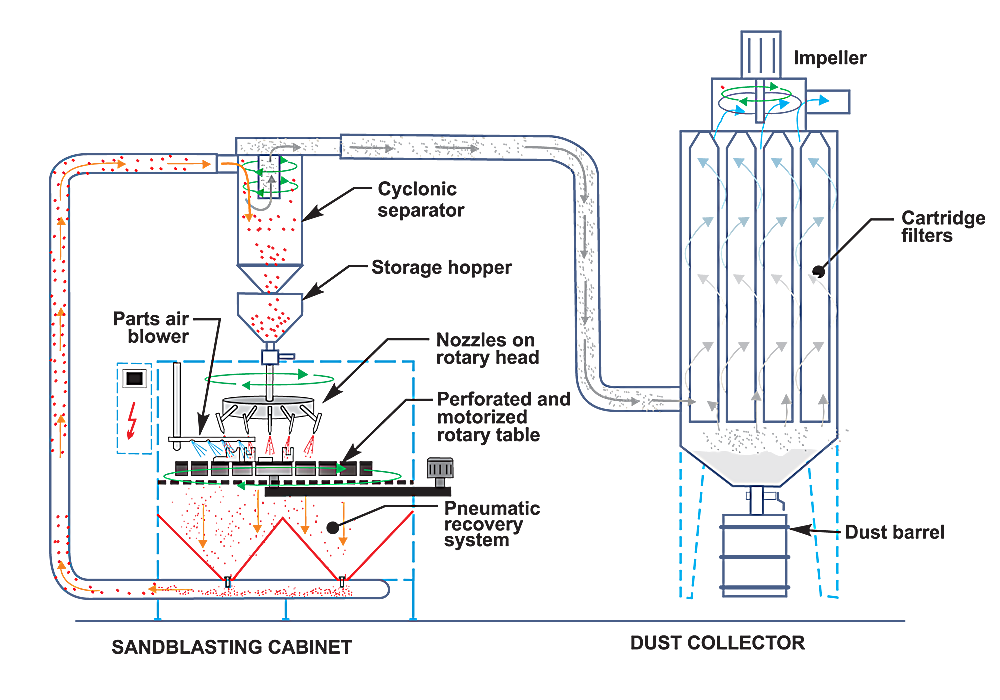

Parts are loaded on a motorized turntable and exposed to the blast stream for a predetermined cycle time. Nozzles can be fixed on a support, a moving shaft, or mounted on a rotary head to provide optimal blast coverage all over the workpiece surface.

Key Features

- Custom Design and Fabrication: Each system is tailored to the customer’s specifications to address all process constraints and for optimal results and productivity.

- Personalized Process: Personalize your process by varying abrasive media, blast nozzle size, blasting pressure, table rotation speed, and blasting cycle time.

- Fully Automated Cycle: Process sequences are controlled by PLC and interfaced with an intuitive HMI touch panel.

- Baghouse Dust Collector: Choose from a range of high-efficiency baghouse dust collectors for both optimal blasting performance and minimizing wear and tear on critical components.

- Media Reclaiming System: Cyclonic separation of contaminated abrasive media for optimal performance – dust and by-products are diverted to the dust collector.

- Electricity: Available in all voltages and frequencies.

- Compliance: Design and door switches comply with OSHA requirements and most local safety jurisdictions.

- Parts Cleaning: Automatic blow-off cycle to remove all dust and contaminants from the freshly-blasted parts.

- Liner Protection: Rubber lining protection on the inner wall, rotating table, and media reclaimer for extended service life.