Description

How it Works

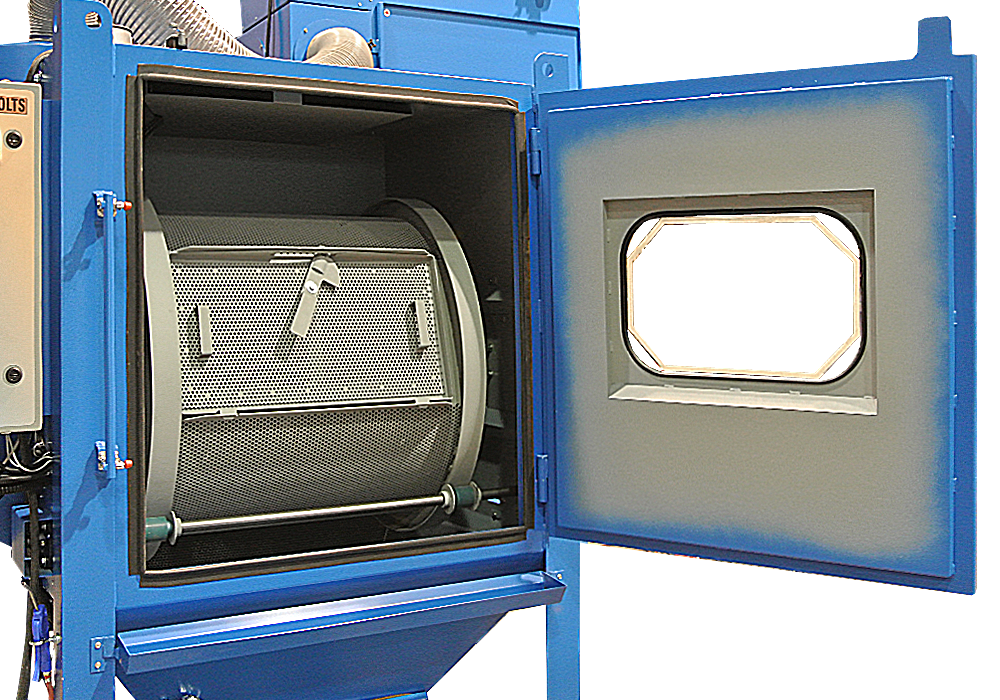

Simply load the parts into the perforated tumbling basket, set the precision timer according to the desired output, and let the Basket Blaster do the rest. By tumbling the parts within abrasive blast streams, these machines deliver consistent finishes automatically.

Key Features

- Heavy-Duty, Coated Tumbling Basket: Available in different mesh sizes and in 1½ cu. ft.

or 3½ cu. ft. loading capacities. - Ergonomic: Unloading chute located at the bottom of the cabinet hopper to facilitate the unloading of parts after the blasting process.

- Custom Design and Fabrication: Each system is tailored to the customer’s specifications to address all process constraints and for optimal results and productivity.

- Personalized Process: Personalize your process by varying abrasive media, blast nozzle size, blasting pressure, table rotation speed, and blasting cycle time.

- Fully Automated Cycle: Process sequences are controlled by PLC and interfaced with an intuitive HMI touch panel.

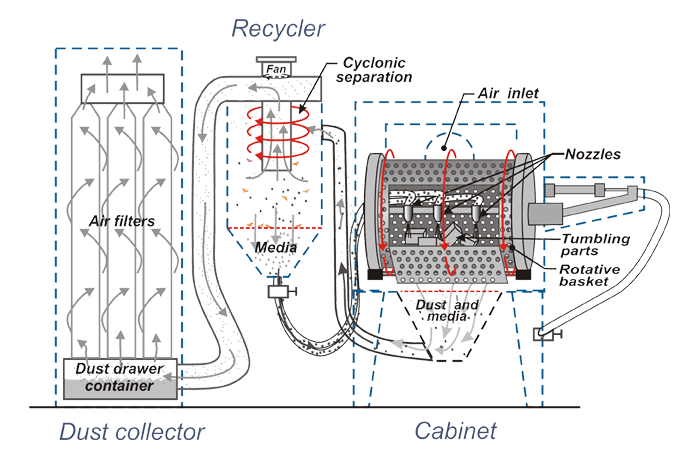

- Baghouse Dust Collector: Choose from a range of high-efficiency baghouse dust collectors for both optimal blasting performance and minimizing wear and tear on critical components.

- Media Reclaiming System: Cyclonic separation of contaminated abrasive media for optimal performance – dust and by-products are diverted to the dust collector.

- Electricity: Available in all voltages and frequencies.

- Compliance: Design and door switches comply with OSHA requirements and most local safety jurisdictions.

- Parts Cleaning: Automatic blow-off cycle to remove all dust and contaminants from the freshly-blasted parts.

- Liner Protection: Rubber lining protection on the inner wall, rotating table, and media reclaimer for extended service life.