Are you using a solvent to flush your paint lines? Are you paying for removal of this paint waste? Paint waste disposal is very expensive. Recovering solvent from paint waste is a proven application for solvent recycling. Companies using on-site solvent recycling spend less money on hazardous waste disposal and spend less on the purchasing of new line-flush chemicals. Additionally, less hazardous material manifested for removal can reduce hazardous waste generator status and also limit cradle to grave responsibility of hazardous chemicals.

The solvents used for line flush are some of the most commonly recycled chemicals.

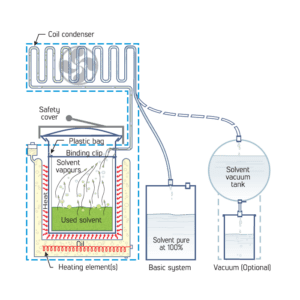

Let’s take a closer look at how recycling your solvent-based line flush works.

What Is Solvent-Based Line Flush?

Solvent-based line flush is used in industrial paint booths to clean out the lines of paint residue and contaminants. As part of the painting process, these residues accumulate, which can cause blockages in paint lines and paint guns if they are not removed regularly. To prevent such blockages, manufacturers must periodically flush out their lines with solvent-based line flush. Additionally, for paint booths doing frequent color changes a proper line flush is integral to prevent contamination in the paint process.

Recycling Solvent-Based Line Flush

The good news is that solvent-based line flush can be recycled without losing its cleaning effectiveness. This means that it can be reused multiple times in order to reduce purchasing costs and save money on disposal fees. By having an on-site solvent recycling system, operators can have a greater quantity of line-flush available to them at all times and are able to perform more thorough clean-outs.

Conclusion: Overall, recycling your solvent based line flush from your industrial paint booth in your manufacturing plant is a great way to reduce both paint waste disposal costs and purchasing costs while improving sustainability at the same time! By reusing this liquid multiple times before disposing of it properly you can save money while still ensuring that product quality remains high throughout the painting process. It’s important to remember that although this process does help save money in the long run, safety should always come first when dealing with hazardous materials like flammable liquids! With that being said however, taking advantage of this cost saving measure is definitely worth considering for any business or manufacturer looking for ways to cut down on unnecessary expenses without sacrificing quality or safety standards!